The following table summarizes the test results. Bentonite was used in this investigation at 5 10 20 and 25 replacement of cement by weight.

Design Proportions For Sccb Mix Design Program Download Scientific Diagram

1 to 06.

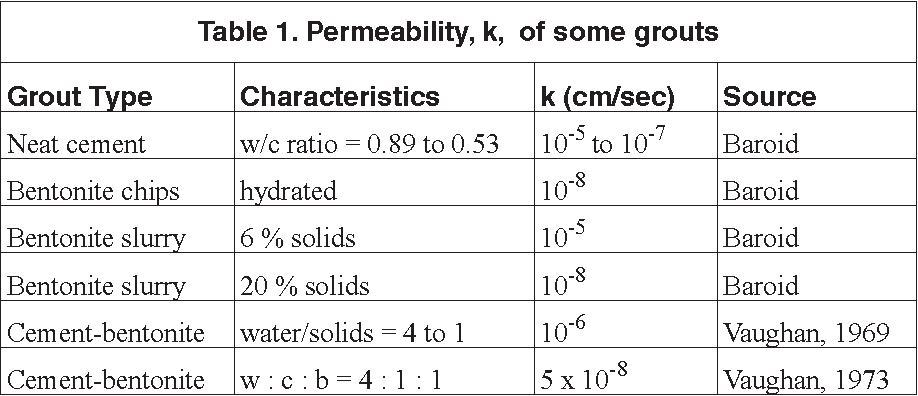

. Dhanalakshmi Experimental Investigation on Concrete by Partial Replacement on Cement by Bentonite and Coarse Aggregate by Steel Slag 5 M. To this must be added an appreciation of slurry workability recognition of proj ect specifics and experience. The viscosity of the mixed slurry is designed to be in the fluid range during the excavation process.

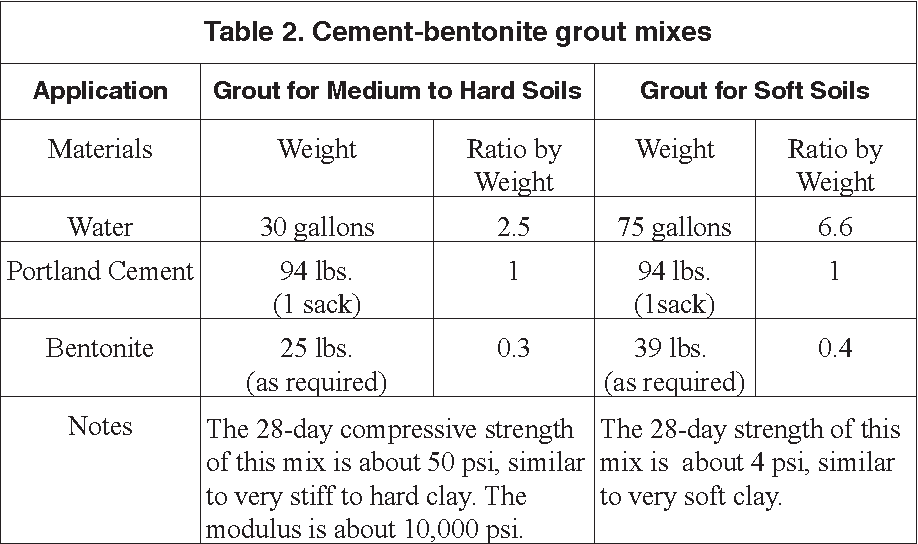

During construction of the barrier wall a trench is excavated under a head of C-B slurry. Commonly the grout mix design is carried out by trialand-error in laboratories- Meanwhile a variety of grout mix is needed to satisfy the required physical and mechanical properties. At the slurry plant cement or some other setting agent is added to the bentonite slurry.

73 water 5 - 6 bentonite 21 - 22 cement by weight RE. Recommended guidelines for concrete mix design proportioning- code of practice. 6 rows properties of the bentonite component once the cement-bentonite grout takes an initial set.

Once the excavation is to full depth the bottom is cleaned and the process moves on. Hooked end steel fibers were also included at various percentagesin the concrete containing 15 replacement of cement by bentonite. Chandrakanth Assistant Professor Department of Civil Engineering SIR C R Reddy College of Engineering Eluru.

Bentonite is used to. INTRODUCTION If the natural soil does not meet the requirements of the. The final mix design consisted of 180 pounds of cement 51 pounds of flyash 2542 pounds of soil dry weight 50 gallons of bentonite slurry and 312 gallons of reservoir water.

It may be dry-blended with the cement or prehydrated in the. Experimental Studies on Concrete with Bentonite as Mineral Admixture M. Bentonite cement earthfill sand unpermeable layer.

Sample Matrix Slurry Mix Permeability cmsec AC-1 AC Mix w Bentonite 5 Bentonite 15 x 10-8 AC-2 AC Mix w Bentonite 05 Dry 5 Bentonite with 05 Dry Bentonite 20 x 10-8 AC-3 AC Mix w Bentonite 10 Dry. The specimens were cast as per mix design. A typical cement-bentonite C-B slurry mixture consists of about 18 percent portland cement 6 percent bentonite and 76 percent water.

Portland Cement ASTM Type I or API Class A B - Portland cement is a mixture of lime alumina magnesia and sulfur trioxide. BENTONITE ADDITIVE TO CEMENT TABLE Percent Bentonite Gallons of water bags of cement Slurry Yield gallons bag Multiply for bags of Bentonite required Multiply for bags of cement required 10 117 1578 0103 56 8 104 1436 0092 61 6 91 1294 0077 68 4 78 1159 0057 76 2 65 1017 0032 87 0 52 882 0000 100. The components are combined and heated and the resulting clinker is ground up and mixed with gypsum to make various types of cement.

For contiguous bored pile wall I normally used the following mixture to get compressive strength of 150kPa. The mixture including 10 bentonite 90 sand is the most economical solution that satisfies the limits values needed for clay core of earth fill dams and clay liners of solid waste storage areas. Ps pw 1 C CGp 1 where pw is the specific gravity of the mixing water assumed to be 10 and Gp is the grain specific gravity of the bentonite powder used to prepare the slurry.

Abs Volume 667 315 X 624 Cement 667 315 339-Total Cementious 667 Miller Stone 1590 26 980 Evert Sand 1242 265 751 Water 300 1 481 1590 260 X 624 1242 265 X 624 481 Air 55 1485 Total 3799 2700 w cm 045 Unit Wt. The range of the volumetric ratio between water and cement is around 6. Concrete Mix Design Data Required for Concrete Mix Design i Concrete Mix Design Stipulation a Characteristic compressive strength required in the field at 28 days grade designation M 25 b Nominal maximum size of aggregate 20 mm c Shape of CA Angular d Degree of workability required at site 50-75 mm slump e Degree of quality control available at site.

As per 10262-2009 mix design code using for the design of the M20 grade of concrete below mentioned details are mix design. The mix resulted in 9 percent cementitious materials a watercementitious material ratio WC of 034 and 09 percent bentonite. Cement bentonite grout mix.

Bentonite swells when mixed with water which expands in the voids causing reduction in the cohesion between aggregates. Studies of grout mix Cement-based grout mix design is commonly carried out based on volumetric ratio to avoid unpractical on-site weighting procedures 1. Cement Bentonite Mix Design.

Cement bentonite mix design You will need a steady hand for this eye catching nail design however its oh-so worth it. The slurry is then pumped from the mix plant to the excavation. The steel fiber content is varied.

The 136 mix has the lowest compressive strength due to the presence of voids in the internal structure of the concrete cubes filled by the bentonite-cement gel since. For instance high flowable neat grout or paste grout that contains only a mix of water and cement. MIX DESIGN CONSIDERATIONS The rational determination of ingredients for cementbentonite requires a knowledge of the material properties their interactions and an understanding of nixing technology.

Cement bentonite grout mix. 1 for common applications. Bentonite can be added to any API class of cement and is commonly used in conjunction with other extenders.

Permeability test results can be found in the mix design report. 14072 Basic Concrete Mix Design Materials Pounds of material SG. Neat cement and bentonite are the two main materials used for making grout slurries.

Bentonite is typically used at concentrations of 1 to 16 BWOC. If you do not have a gradual hand nevertheless there are lots of nail stickers stamps or head on to your neighborhood nail salon so they can replicate it for you. For a far more subdued design attempt a nude nail.

However currently there are hardly any available practical mix design methods of cement-based grout. Basic Concrete Mix Design Materials Pounds of material SG. Irawanfirmansyah Geotechnical 28 Jun 10 0423.

Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. If the concentration Cs is expressed as kilograms of bentonite per cubic meter of final slurry then the formula becomes.

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Concrete Mix Design Used For Laboratory Tests Download Table

2 Summary Of Cement Bentonite Grout Ratios Download Scientific Diagram

Mixture Designs Proportions Of Plastic Concrete Mixes Download Table

Blend Mix Proportions And Blend Slurry Properties Download Table

Mixture Designs Proportions Of Plastic Concrete Mixes Download Table

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

0 comments

Post a Comment